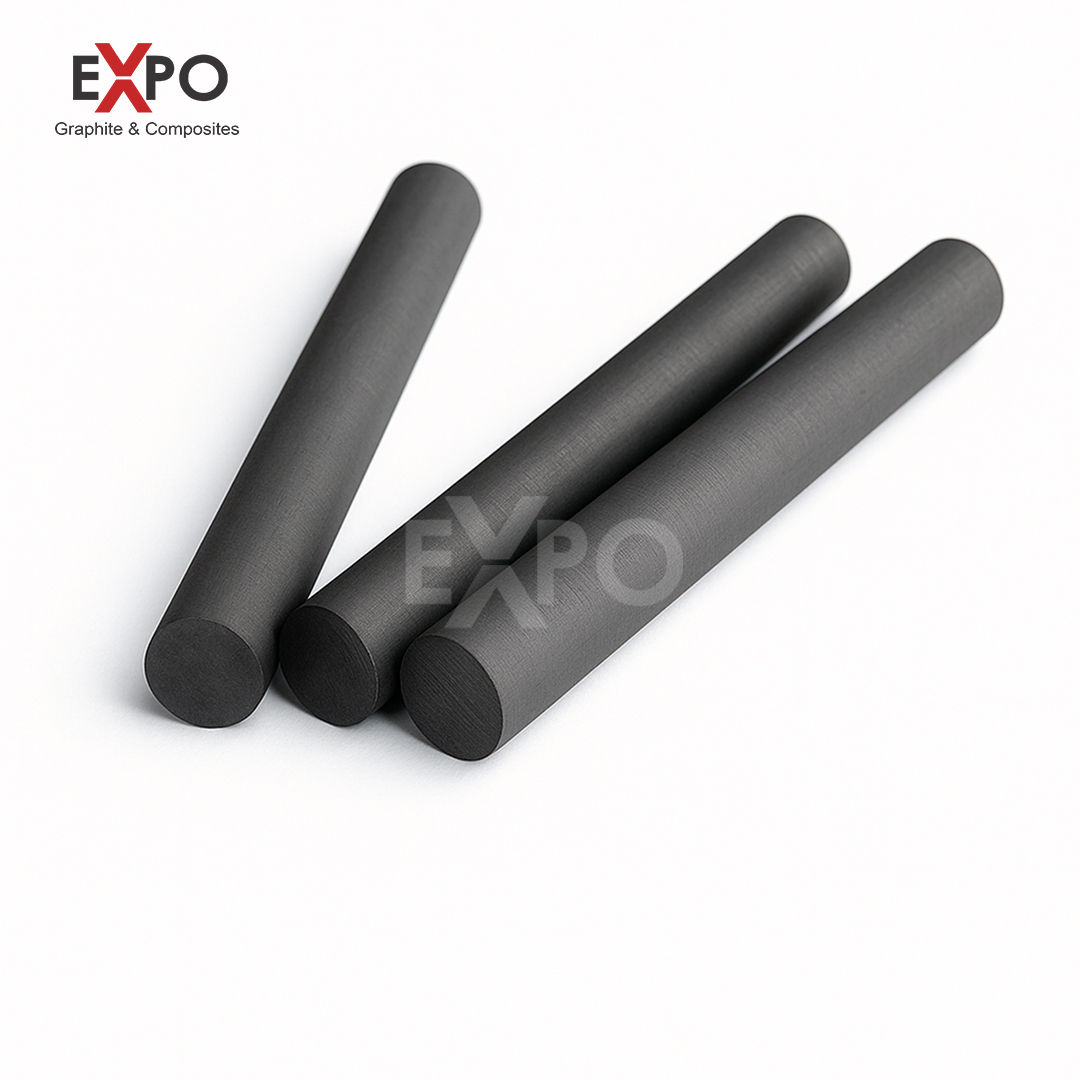

Graphite Electrode Rod

Graphite Electrode Rod is a strong graphite stick used in big ovens to melt metal with electricity. It helps carry electricity and can get very hot without breaking. These rods are important for making steel and other metals. They last a long time and help factories work better and faster.

Description

Electricity is an important part of our daily life and industrial work. One of the key products that helps in using electricity in big industries is the graphite electrode rod. As the name says, this rod is mainly made from graphite – a special kind of carbon that can handle high heat and conduct electricity very well.

At Expo Machine Tools, we have spent years learning about graphite and improving our graphite products. Because of our experience, we make high-quality graphite electrode rods that are strong, dependable, and perfect for many industrial uses.

Graphite is not only strong, but also one of the best materials for carrying electricity. Scientists have even found that graphite might be used instead of silicon in future computers. Other graphite products like graphite molds, graphite rods, graphite discs, and graphite bolts are also very useful in industries where high heat and electricity are involved.

Let’s look at how to safely use and connect graphite electrode rods:

- Dry the Rod if Wet: If the rod is wet, make sure to dry it completely before using it.

- Check the Cap and Wire: Clean the protective cap and check that the wire inside the rod is not damaged.

- Clean the Threads: Clean the inside threads of the hole and the surface of the spare rod before connecting.

- Insert the Connector: Put the connector into the hole of the electrode, then attach the expander tool to the other end.

- Handle Carefully: When laying down the rod, be careful not to hit it against anything.

- Hang and Clean Before Connecting: Hang the spare rod above the one already in place. When they are 10-20 mm apart, clean both ends again with air to remove any dust.

Tighten the Rod: Finally, tighten the rod so that the connection is strong and secure.