Expo Graphite and Composites

Powering Innovation in Fuel Cells and Batteries

Explore cutting-edge graphite and composite solutions designed to boost efficiency, performance, and durability in modern fuel cells and batteries. These materials play a crucial role in enabling cleaner energy by supporting high conductivity, thermal stability, and corrosion resistance. From electric vehicles to industrial power systems, our graphite components enhance reliability and lifespan under demanding conditions. Carbon composites offer lightweight strength for structural support, while coated graphite ensures protection in harsh environments. Together, they pave the way for high-performance, sustainable energy technologies.

Request QuoteWhat is the Role of Graphite and Composites in Fuel Cells and Batteries?

Graphite and composite materials are cornerstone elements in the evolution of fuel cells and batteries, delivering critical properties that transform energy systems. Graphite, a naturally occurring form of carbon, boasts exceptional electrical conductivity, reaching values up to 10^6 Siemens per meter (S/m), allowing efficient electron transfer in electrochemical reactions. Its thermal stability, with a melting point around 3,650°C, enables it to withstand the intense heat generated in fuel cell stacks and battery operations. Additionally, graphite’s resistance to corrosion ensures longevity in harsh chemical environments, such as the acidic conditions of fuel cells. Carbon-carbon (C/C) composites, on the other hand, combine carbon fibers and matrices to provide remarkable mechanical strength, with tensile strengths up to 1,000 megapascals (MPa), and thermal resilience, making them ideal for structural components. These materials support a wide range of applications, from powering electric vehicles with high-capacity batteries to enabling clean energy generation through fuel cells for residential, industrial, and transportation needs. By optimizing conductivity, stability, and durability, graphite and composites drive the efficiency and reliability of next-generation energy solutions.

How Are Fuel Cells and Batteries Enhanced by Graphite and Composites?

The performance of fuel cells and batteries hinges on advanced materials tailored for precision and resilience. Graphite and composites elevate these technologies through the following contributions:

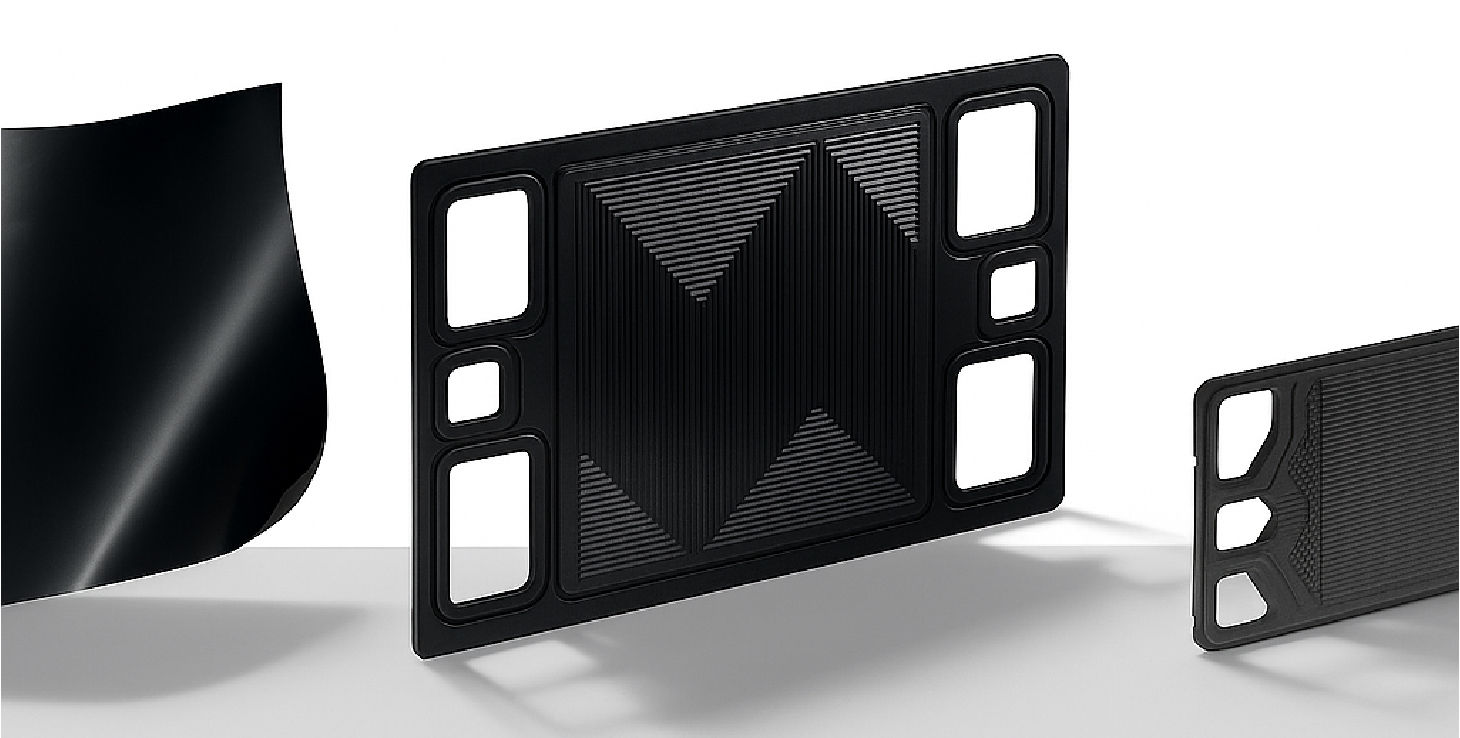

- Graphite Bipolar Plates in Fuel Cells: In proton exchange membrane (PEM) fuel cells, graphite bipolar plates are essential for channeling hydrogen and oxygen gases to facilitate the electrochemical reaction that generates electricity. With an electrical conductivity of approximately 10^5 S/m, these plates ensure efficient electron flow, supporting power outputs that can reach 1 watt per square centimeter (W/cm²). Their corrosion resistance allows them to endure acidic environments (pH below 3), common in PEM fuel cells, without degrading, ensuring consistent performance over thousands of operating hours.

- Graphite Anodes in Batteries:In lithium-ion batteries, high-purity graphite serves as the anode material, storing lithium ions during charging. It offers a practical capacity of around 350 milliampere-hours per gram (mAh/g), closely approaching its theoretical limit of 372 mAh/g. With low irreversible capacity loss (less than 10%) and the ability to withstand over 1,000 charge-discharge cycles, graphite anodes enable rapid charging, high energy density, and extended battery life, critical for electric vehicles, portable electronics, and grid storage.

- Carbon-Carbon Composites for Structural Support: Carbon-carbon (C/C) composites deliver a unique blend of lightweight design and robust strength, with a thermal conductivity of approximately 100 watts per meter-Kelvin (W/m·K) and tensile strength up to 1,000 MPa. These properties make them ideal for supporting fuel cell stacks operating at elevated temperatures of 600 to 1,000°C, as seen in solid oxide fuel cells (SOFCs), and for reinforcing battery casings under mechanical stress, ensuring structural integrity in demanding applications.

- Carbon Felt for Thermal and Electrical Management: Carbon felt, a porous carbon-based material, provides exceptional thermal insulation, with a conductivity as low as 0.2 W/m·K, minimizing heat loss in fuel cells and batteries. Simultaneously, it conducts electricity effectively, managing current flow within systems. This dual functionality optimizes thermal stability and electrical efficiency, critical for maintaining performance during high-temperature fuel cell operation and battery cycling

- ACoatings for Durability: Protective coatings, such as silicon carbide (SiC), with a hardness of up to 25 gigapascals (GPa), shield graphite components from oxidative and electrolytic degradation. In fuel cells, these coatings resist reactive gases like oxygen and water vapor, while in batteries, they protect against corrosive electrolytes, extending component lifespan beyond 5,000 hours in harsh chemical environments.

Benefits of Expo Graphite and Composite Solutions

Expo Graphite and Composite delivers tailored solutions that elevate fuel cell and battery performance through advanced materials. Key benefits include:

Enhanced Electrical Conductivity:

ROur high-purity graphite, with conductivity ranging from 10^5 to 10^6 S/m, ensures efficient electron transfer, enabling fuel cells to achieve power densities up to 1 W/cm² and batteries to support rapid charging, critical for high-performance energy systems.

Superior Thermal Stability:

Our materials remain stable at temperatures exceeding 3,000°C, handling the intense heat of fuel cell stacks (600–1,000°C in SOFCs) and mitigating thermal runaway risks in batteries, ensuring reliable operation under extreme conditions.

Corrosion Resistance:

SSilicon carbide (SiC) coatings protect components in acidic (pH < 3) and oxidative environments, extending service life beyond 5,000 hours, reducing maintenance costs, and ensuring consistent performance in fuel cells and batteries.

Lightweight Strength:

Carbon-carbon composites, with a density of approximately 1.8 grams per cubic centimeter (g/cm³) and tensile strength of 1,000 MPa, offer lightweight yet robust support, ideal for portable devices, electric vehicles.

High Capacity and Efficiency:

Our graphite anodes deliver a capacity of around 350 mAh/g, enabling lithium-ion batteries to achieve energy densities of 200–300 watt-hours per kilogram (Wh/kg), providing longer runtime for consumer and industrial applications.

Customizable Solutions:

We tailor components to meet specific needs, such as voltage requirements (e.g., 1.2V for fuel cells, 3.7V for batteries), current demands, and thermal profiles, ensuring optimal integration into your unique energy systems.

Annealing Techniques

The wafer is heat-treated to activate implanted ions and heal crystal damage, ensuring proper electrical function and structural integrity.

Wafer Dicing and Packaging

Completed wafers are tested, cut into chips, bonded to connectors, and packaged for protection, ready for use in electronic devices.

Applications of Graphite and Composites

Proton Exchange Membrane (PEM) Fuel Cells:

Graphite bipolar plates facilitate power densities of 0.5 to 1 W/cm², enabling efficient, clean energy production for vehicles, such as fuel cell electric vehicles (FCEVs), and stationary power systems for homes and businesses, with conversion efficiencies exceeding 50%.

Lithium-Ion Batteries:

Graphite anodes provide energy densities of 200–300 Wh/kg and coulombic efficiencies above 90%, powering electric vehicles, consumer electronics like smartphones and laptops, and grid storage systems for renewable energy integration.

Solid Oxide Fuel Cells (SOFCs):

Carbon-carbon composites and graphite components withstand temperatures of 600 to 1,000°C, supporting reliable, high-efficiency power generation for industrial applications, such as combined heat and power systems in factories.