Expo Graphite and Composites

Powering Innovation in the Glass Industry

Transform your glass manufacturing operations with our cutting-edge graphite and composite solutions that deliver unparalleled efficiency, precision, and quality across every production stage—from initial melting through final forming and finishing processes.

Request QuoteWhat is the Role of Graphite and Composites in the Glass Industry?

Graphite and composite materials play a pivotal role in modern glass production, offering exceptional properties that enhance every stage of the manufacturing process. Graphite, known for its high thermal conductivity, resistance to extreme temperatures, and chemical inertness, is ideal for handling molten glass in harsh environments. Composites, such as carbon-carbon (C/C) materials, provide structural strength and thermal stability, ensuring durability and precision. Together, these materials improve furnace performance, enable precise shaping, and maintain high-purity standards, making them indispensable for producing everything from everyday glassware to advanced specialty glass for optical and display applications

How to Improve Glass Melting and Forming Efficiency with Graphite Components?

Graphite and composite materials are game-changers for glass production, optimizing efficiency, quality, and longevity. Here’s how our solutions elevate your process:

- Enhancing Glass Furnace Performance with Graphite Heating Elements: T Graphite heating elements deliver exceptional thermal conductivity and resistance to high temperatures, ensuring uniform heating in furnaces. This reduces energy consumption, speeds up melting, and extends furnace lifespan, lowering operational costs.

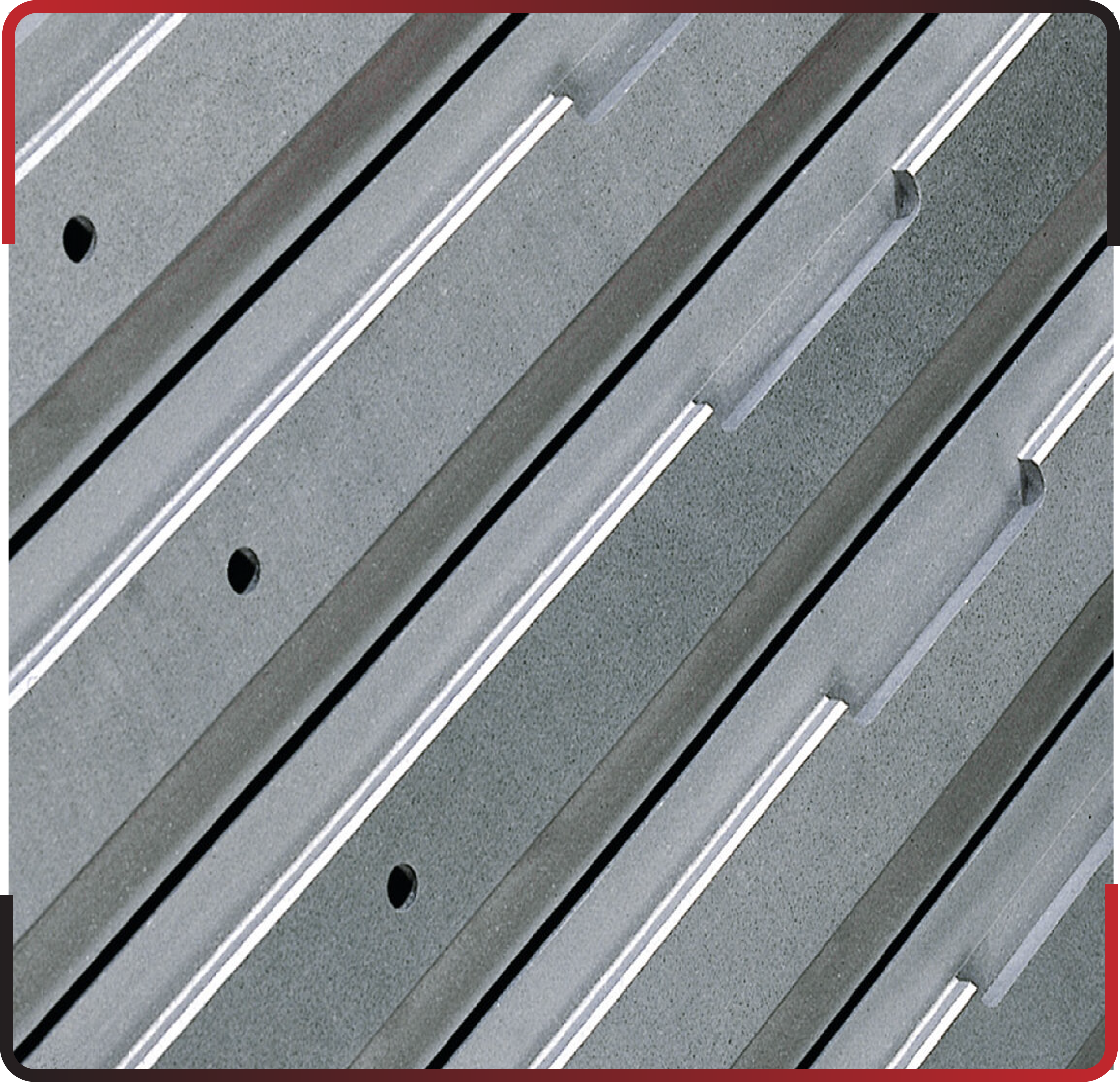

- The Role of Graphite in Glass Shaping and Forming Molds: Graphite molds offer a smooth, non-stick surface and high thermal stability, enabling precise shaping of molten glass. Their durability reduces wear, ensuring consistent quality across large production runs.

- Carbon-Carbon Composites for Structural and Thermal Stability in Glass Production:Carbon-carbon (C/C) composites combine lightweight strength with resistance to thermal shock and deformation. They’re ideal for fixtures and supports, maintaining stability in high-heat environments.

- Benefits of Using Carbon Felt and Insulation Boards in Glass Kilns: Carbon felt and insulation boards minimize heat loss, maintaining consistent temperatures in kilns. This improves energy efficiency, reduces cycle times, and enhances the quality of annealed or fired glass.

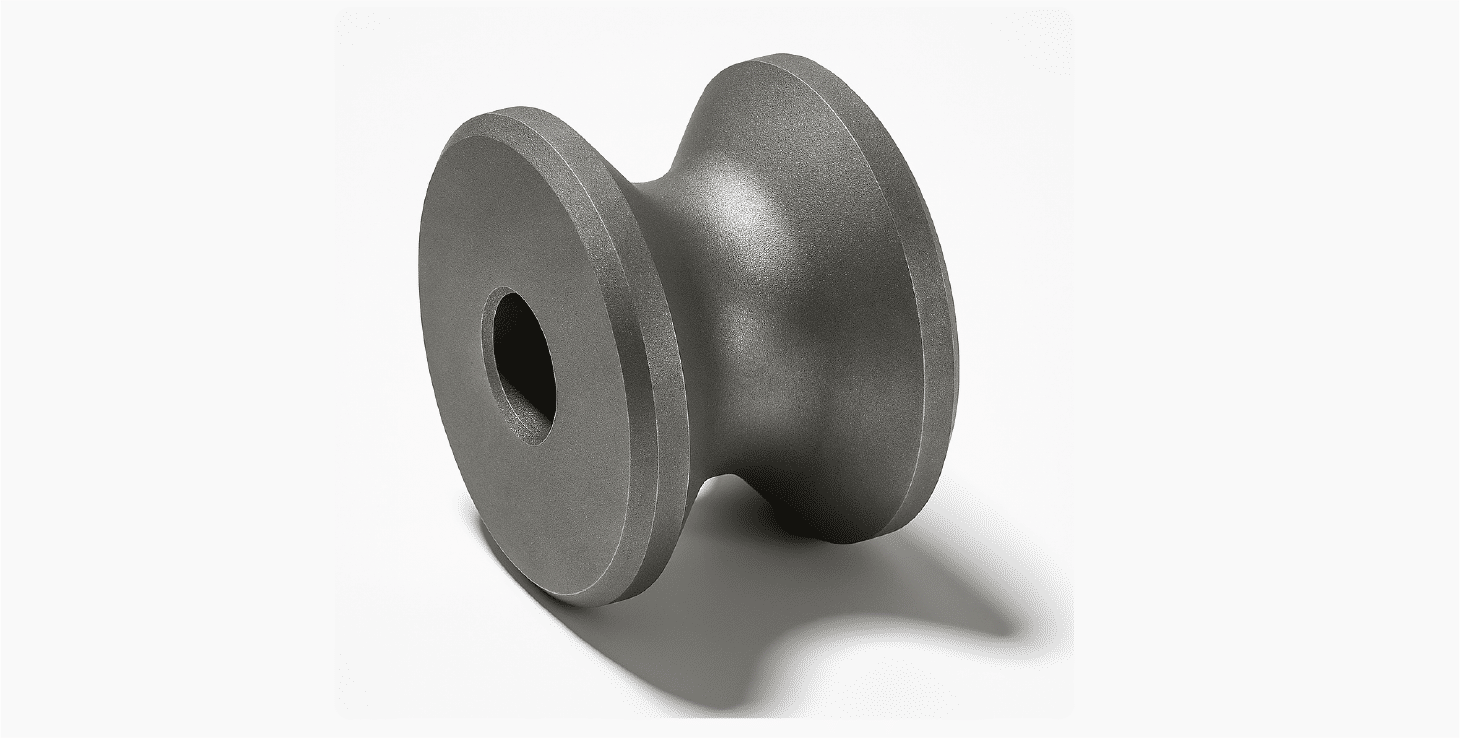

- Why Graphite Crucibles and Susceptors Are Ideal for High-Purity Glass Applications: Graphite crucibles and susceptors resist chemical reactions with molten glass, ensuring no contamination. Their high thermal conductivity supports uniform heating, critical for high-purity optical and specialty glass.

- How SiC and TaC Coatings Protect Graphite Parts in Corrosive Glassmaking Environments: Silicon carbide (SiC) and tantalum carbide (TaC) coatings shield graphite components from corrosive molten glass and oxidative atmospheres, extending their lifespan and maintaining performance in harsh conditions.

Applications of Graphite in Specialty Glass

Optical Glass

High-purity crucibles and molds ensure flawless clarity.

Borosilicate Glass

Thermal-resistant graphite components support high-temp forming.

Display Glass

Graphite and C/C composites enable precision in thin, durable glass.